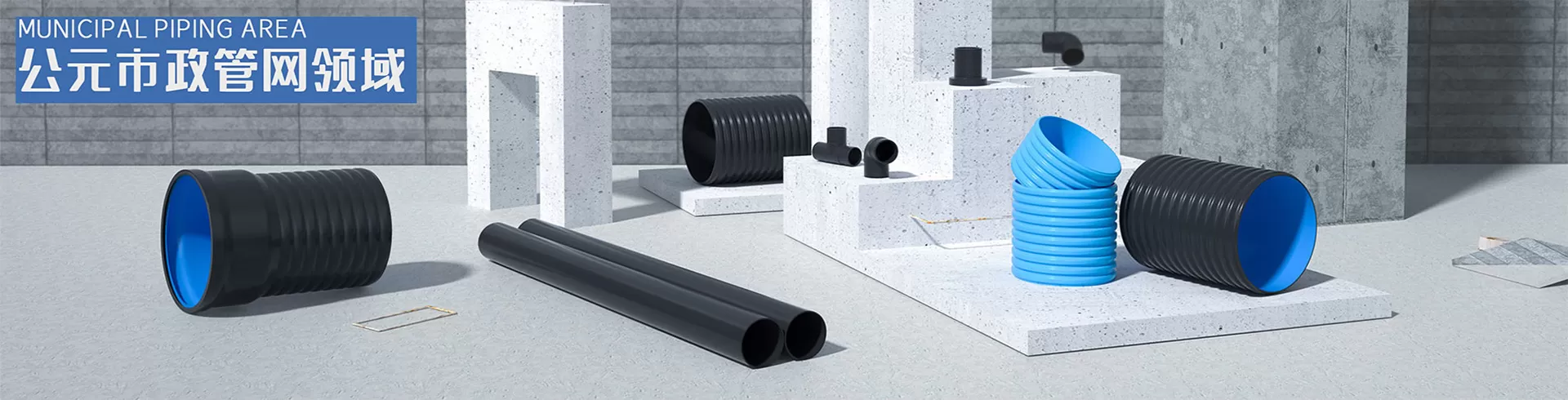

As the "main pipeline" in the fields of urban water supply, gas transmission and municipal drainage,

.jpg)

PE pipes are widely used due to their corrosion resistance, lightness and easy installation. In the process of construction or renovation, cutting PE pipes is a common operation - such as adjusting the length of the pipeline and dealing with damaged pipe sections, but many people often ignore a key detail: should the cut PE pipe be sealed?

The answer is very clear: PE pipes must be sealed in time after cutting. This seemingly "insignificant" step actually directly affects the service life and use effect of the pipeline. There are three reasons that cannot be ignored behind it.

Why should the PE pipe be sealed after cutting?

The first is to prevent the intrusion of debris. The cut pipe end is completely open, and dust, sand, gravel, and debris at the construction site, or insects and dead leaves in the storage environment, can easily fall into the pipe. Once these sundries enter, they may clog the faucet, water meter (water supply pipeline), wear the gas meter or valve (gas pipeline), and even accumulate in the drain pipe, resulting in poor drainage.

is followed by anti-moisture intrusion. Although the PE pipe is resistant to moisture, if water vapor enters the pipe, the trouble will slowly "ferment": the water vapor in the water supply pipe may breed bacteria and affect the water quality; the moisture in the gas pipe will react with a small amount of impurities and may corrode the pipe fittings; even in the drainage pipe, long-term moisture may make the inner wall of the pipe end adhere to dirt and speed up the clogging speed.

Finally, protect the integrity of the pipe end. The end of the freshly cut PE pipe may have burrs, or the end face may be uneven due to the cutting tool. If it is not sealed, the end of the pipe is easy to be bumped, scratched during transportation or storage, resulting in deformation or cracks - when connecting the pipe fittings later, the deformed end cannot be tightly fitted with the joint, and water leakage and air leakage are likely to occur.

the consequences of not sealing, more troublesome than you think

many people think "just put it for a while, no need to seal", but in fact, even if it is opened for a short time, it may also bury hidden dangers:

- water supply pipe: sand and gravel may be stuck in the pipeline after entering the bend, need to be cleaned with high-pressure water, serious pipe replacement;

- gas pipe: fine dust will wear the metering parts of the gas meter, resulting in inaccurate metering, and even card astringent valve;

- drainage pipe: sediment accumulation will reduce the drainage section, resulting in bath water can not be drained, or kitchen backwater.

The correct sealing method is divided into 3 scenarios

sealing is not "just plug it", according to the use of the scene to choose the right method:

1. Temporary sealing (construction/storage)

If the pipeline needs to be transported or temporarily stored, it is most convenient to use a special plastic plug - choose a plug that matches the diameter of the pipe and plug the end of the pipe vigorously; when there is no plug, wrap the end of the pipe tightly with a clean plastic film, and then tie it firmly with a cable tie, leaving no gaps.

2. Permanent sealing (end pipe)

If the end of the pipe (such as the end of the water supply branch, the end of the gas reserve), hot melt welding with PE pipe cap: The pipe cap and the pipe are of the same material, align the pipe end when welding, control the temperature and time, and ensure complete sealing.

3. The key point to note

polish the burr on the end of the pipe before sealing, otherwise it will puncture the plastic film or cause the plug to loosen; check it after sealing - the plug should not be pushed, and the plastic film should not leak.

The big attention in the small details

PE pipe "durability" is never based on "natural advantages", but the accumulation of details in each step. The sealing after cutting is such an "invisible but important" step: taking a few minutes to do it well can avoid the trouble of maintenance in the later days.

After all, the essence of pipeline installation is to "plug every possible loophole" - from cutting to sealing, from connection to pressure test, every step cannot be saved. After all, no matter how easy the PE pipe is to use, it cannot withstand the consumption of "details lazy".